Thoughts On R&D

We strive for technological innovation and R&D activities to constantly demonstrate originality in the field of vacuum technology applied equipment. In addition, to ensure that our equipment can be used safely and comfortably, we are also working on R&D aimed at realizing services that incorporate next-generation sensing technology into the equipment and maintain optimal operating conditions.

R&D System

Technology Development Department

R&D based on market needs

Development of elemental technologies

Equipment

development

Process

development

We have organized task force-type project teams to promote R&D activities so that we can respond quickly to market demands.

Ion Source Development

Operating principle and concept of ion source

The main ion sources installed in the vacuum thin film deposition equipment are roughly divided into the gridded type and gridless type in the electrostatic acceleration method.

Ion sources consist of three areas, namely, (1) ion generation (ionization), (2) ion acceleration, and (3) ion neutralization. Select the ion source to install in the vacuum equipment according to the thin film deposition application.

Gridded Ion Source

Gridless Ion Source

Gridded Ion Source

The ion generation methods of gridded ion sources are broadly divided into three types, namely the DC discharge type, high-frequency induction discharge type, and microwave discharge type.

The generated ions are accelerated by applying a high voltage to a porous electrode consisting of two or three sheets.

Showa Shinku offers a lineup of DC discharge type (Kaufman type) and high-frequency induction discharge type ion sources.

Source: Hiroki Watanabe and Haruki Takegahara (Tokyo Metropolitan University), “Ion Engine Operating Principles and Installation Status” (Space Japan Review, No. 70, October / November 2010)

IGF series [Gridded ion source (DC discharge type)]

The IGF series is installed in ion beam etching equipment that performs microfabrication.

Microfabrication is performed by accelerating ions extracted from the generated plasma and colliding them with the material being processed.

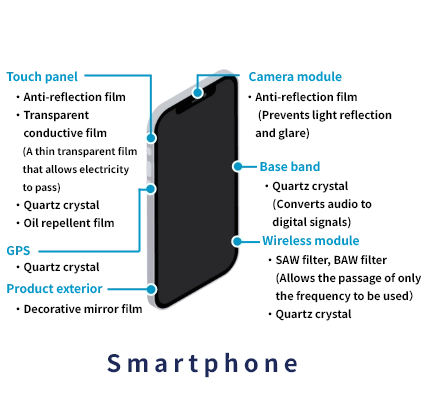

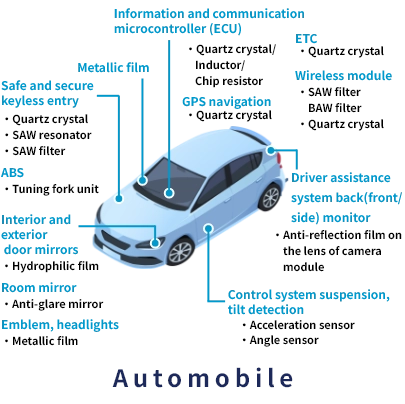

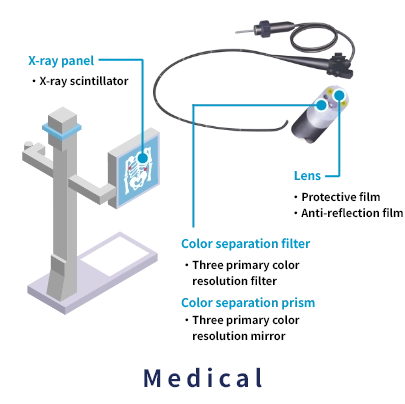

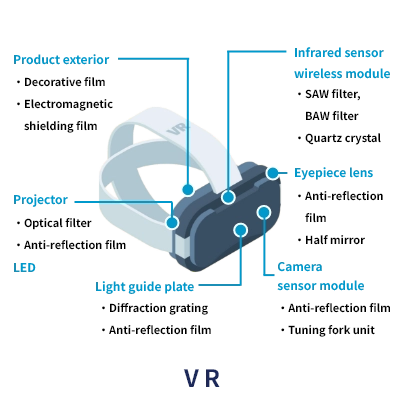

This is applied in trimming for flattening and removing unevenness of the wafer surface, and for frequency adjustment of quartz crystals and SAW filters.

ISG series [Gridded ion source (High-frequency induction discharge type)]

The ISG series is installed in Ion Assisted Deposition (IAD) equipment.

By irradiating the target with an ion beam while depositing, dense (high-density) thin films can be formed.

This is applied in adjustment of density of thin films as devices become smaller and thinner.

This series is used for a variety of purposes, from non-shift films for optical filters to improving adhesion on resin substrates.

Gridless Ion Source

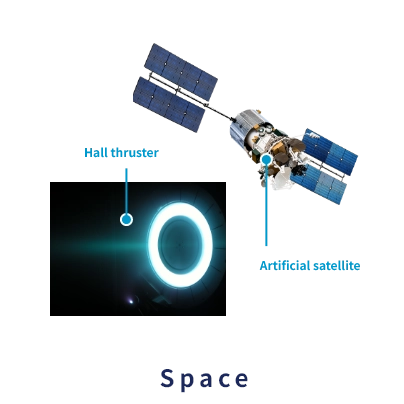

The gridless ion source developed by Showa Shinku is a hall-accelerated type ion source with characteristics that are in between the end hall type and the gridded type.

Like the gridded ion sources, this is an ion source that uses electrostatic acceleration method.

The hall-accelerated type is designed so that the magnetic field and electric field intersect, which traps electrons emitted from the cathode source and ionizes the introduced gas to generate ions. The ions are accelerated by the anode potential and emitted as an ion beam. The emitted ion beam is neutralized by electrons emitted from the cathode source.

The main difference from the gridded type is that ion generation and acceleration are performed simultaneously.

This type has also been used for a long time in vacuum thin film deposition equipment.

ISH series [Gridless ion source (Hall-accelerated type)]

The ISH series, like the ISG series (gridded ion source), is installed in ion-assisted deposition equipment.

This series is simple and compact, yet capable of high-output ion irradiation, so it achieves sufficient current density and distribution even when installed in large equipment.

The gridless design reduces running costs and shortens maintenance time.

![ISH series [Gridless ion source (Hall-accelerated type)]](img/img13.webp)

Technical Exchange Meeting

We hold technical exchange meetings to introduce the latest status and results of our R&D efforts to our customers and to receive their opinions and requests. We will reflect these opinions and requests in further improving the performance and quality of our products.

History

Fiscal year 2019

Date of meeting: November 12, 2019

Venue: Hotel Grand Palace

The event was canceled from FY 2020 to 2022 (due to COVID-19)

Fiscal year 2023

Date of meeting: November 8, 2023

Venue: InterContinental Yokohama Grand

Fiscal year 2024

Date of meeting: October 31, 2024

Venue: InterContinental Yokohama Grand

Fiscal year 2025

Date of meeting: November 11, 2025

Venue: InterContinental Yokohama Grand

List Of Supporting Industry Program

The Strategic Core Technology Advancement Program (Supporting Industry Program) is a program implemented by the Ministry of Economy, Trade and Industry to support R&D, prototype development, and commercialization efforts that lead to the advancement of specific core manufacturing technologies (12 fields) conducted by SMEs and small-scale businesses in collaboration with universities and public testing/research laboratories, with the aim of strengthening the international competitiveness of Japan’s manufacturing industry and creating new industries.

Several R&D themes conducted by Showa Shinku have been adopted.

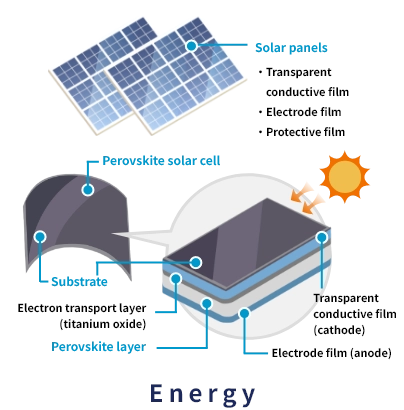

- ・R&D of practical use of alternative materials for ITO transparent conductive films

- ・R&D of frequency adjustment technology to support the miniaturization of quartz crystals

- ・Development of flexible substrate deposition process for ITO-alternative transparent conductive film

- ・R&D of vacuum transfer and heat sealing equipment for quartz crystals to support miniaturization

- ・Development of a sputtering equipment for SiO2 film formation that contributes to improved productivity of SAW filters

List Of Other Development Public Institution Support Program

- ・Prototype development of vacuum deposition equipment for adjusting the chromaticity of white LED light-emitting devices (Ministry of Economy, Trade and Industry: Support project for prototype development, etc., for small and medium-sized manufacturing companies and small-scale businesses)

- ・Development of a high usage efficiency cathode for vacuum sputtering equipment (Sagamihara City: Sagamihara City small and medium enterprise R&D support program)

- ・Development of vacuum evaporation equipment for SAW filter comb-type electrode film formation (Ministry of Economy, Trade and Industry: Support program for innovation in manufacturing, commerce and services)

Pre-purchase demonstration